Zinc plating has been used for decades as a way to protect metals, most commonly stainless steel, from any type of rust and corrosion through exposure to the atmosphere. As it is more costly than other protective coatings, it is typically reserved for smaller parts or essential components rather than for larger things such as sheet plating.

The Look

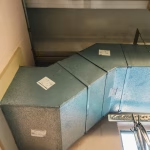

The look of metal plated with zinc is very distinct. In the normal form, it will be a dull type of light to light-medium color of gray. It is not naturally highly reflective, creating more of a matte to an almost brushed type of look.

However, with new processes the finish and the final color of zinc plating can be tweaked to create a brighter, more lustrous finish that is a very light gray in color to almost an off-white.

To create the different looks, various brightening agents can be used. It is important to carefully control these additives to preserve the benefits of the coating in protecting the underlying steel or metal alloy.

The Protection

Adding zinc to the surface of stainless steel can preserve the surface of the metal for up to 30 years, even under extreme environmental exposure. Without the coating, rust and corrosion will be evident within two years, and very noticeable within five.

The natural salts in zinc, which are insoluble, actually bond with the surface of the steel. If there is a scratch or a dent in the surface these insoluble salt ions will move over the exposure surface, literally coating the surface and providing ongoing protection without the need to re-coat the surface.

Structural Integrity

With zinc plating, the structural integrity of the underlying base metal is not compromised by corrosion or rusting. This ensures that the strength of the metal is not compromised, and there is less need to replace components because of surface damage issues.

The Process

The process of plating with zinc is similar to plating with other metals. It can be completed through barrel or rack plating processes, with the size, shape and complexity of the parts often playing into the decision about which is the most effective plating method.

For parts requiring zinc as the plating, it is essential to choose a company with experience and expertise in the plating process. It will also be important to ensure the company has the capacity to complete your order on your schedule and within your budget.