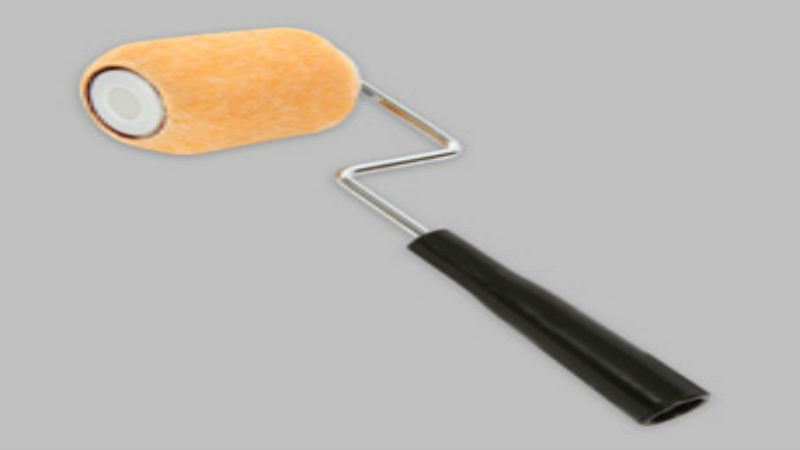

In the painting profession, time is one of your biggest concerns. You want to give your customers high-quality results at the most affordable prices. If you hurry the work, the quality suffers, but when you find something to speed up the job (and maintain quality) everyone wins. A good high density foam paint roller can help to increase your efficiency and here are some of the benefits it has to offer.

What Does High Density Mean?

Foam is either open or closed cell material. During the process of manufacturing, inflating agents are used, and sodium bicarbonate is common because it creates bubbles in the foam. These bubbles make cells, and they are either separate from each other (closed) or connected (open cell). A high density foam paint roller is usually made from highly dense closed cell foam. It has a greater weight per inch, and this makes a durable roller.

Many cheap rollers are low density, and they sometimes fall apart while you are using them because they cannot take a lot of friction. Some are too absorbent, and they create holes or gaps in the paint while you are using them. This can cause air bubbles in the paint.

Benefits of High Density Foam Paint Roller Products

Many smaller cigar-shaped rollers are higher density. These rollers are perfect for finishing cabinets because they give you a very smooth and even finish. You can complete the job quicker and provide a high-quality finish which your customers appreciate.

Downside

The only downside is cost, but this offset by the longevity and quality of work these rollers produce. In fact, you can clean them and reuse them for other projects. This saves money on supplies, and you spend less time ordering and waiting for your supplies. This is the reason most professionals opt for the best available tools and equipment.