In any type of application where sanitary processing is required, having the right equipment and options in all aspects of the system is essential for optimal production. It is also important to prevent inconsistencies in production that can alter the taste, quality and even the shelf-life of the food or beverage.

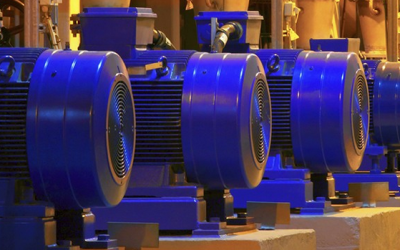

An important part of any food and beverage production is the sanitary centrifugal pump. In general, these pumps are long-lasting and dependable, with limited to low maintenance requirements. However, even with the best care, they eventually need to be replaced.

Choosing a replacement sanitary centrifugal pump is not as simple as reordering the current pump and installing it in the system. In many cases, particularly with the older centrifugal pumps, new options and features in different brands and models on the market can add to the system performance and efficiency.

Brands

There are new brands and models of centrifugal pumps for the sanitary processing industry in the market. Not all of these pumps are the same, and some of the lesser known brands or new brands are largely untested in industrial applications.

It is highly recommended to choose a brand name that is recognized in the industry. This ensures the pump has the reliability and performance needed for sanitary processing operations. It is also important to remember that major brands have 3F and typically USDA and FDA approval, while some imported brands may not.

Consider the System

Make sure any replacement sanitary centrifugal pump is designed to meet all of the operating conditions of the system. If you are planning on making changes in any of these parameters, including pressure, volume or temperature, ensure the replacement pump is rated to meet these new requirements to avoid having to replace the pump again in the near future.