You’ve probably never stopped to think about how metal looks as smooth and shiny as it does. After all, metal parts in a busy machine that are constantly undergoing wear and tear don’t stay looking new just out of chance. You can thank tumble and centrifugal barrel finishing for that! The process is also known as tumbling or rumbling, and is a technique for polishing or smoothing a rough surface on relatively small parts. It is very useful for a variety of important applications. Read on for some more information on the different varieties of this fascinating process.

Stone

Centrifugal barrel finishing is often used for the polishing of gemstones that you’ll find in jewelry, art, and decorative items. A full tumble polish for rough rocks can take up to five weeks, and is typically done in a five-step process. The stone is first smoothed with a coarse grit and then washed and smoothed with another round of finer grits. The stone is then “pre-polished” during a washing cycle, and then finally polished using a polishing powder. The exact polishing time depends on the hardness of the rock and the degree of smoothing desired.

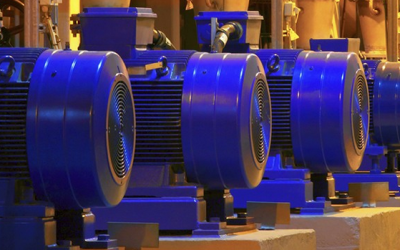

Metal

Metal tumbling is used to deburr and clean pieces of metal. The process is relatively simple. A large barrel is filled with materials that need to be polished, filled with the water or other lubricants, and then rotated. As the barrel is rotated, the parts will rise until gravity causes the top layer to “landslide” down to the opposite side. This process is very economical since large batches of the parts can be run with little to no observation from the operator. This method can take between six and twenty-four hours.

Glass

Centrifugal barrel finishing can even be used for stained glass shards for mosaic glass. No abrasive is used in the process to avoid clouding the glass. The object of the tumbling is to remove the sharp edges from the glass so that it can be handled safely and used for art projects, decorations, jewelry and more. This process only requires around eight hours of tumbling.