Understanding the science behind radio frequency welding services is helpful in recognizing the advantages of this process over other methods to glue or fasten plastics. As it includes a molecular level change to both materials and a true fusion to create the seam or the bond area, it is a strong, durable and highly efficient way to develop perfect seams on every unit produced.

The Basics of RF Welding

RF welding or sealing uses the energy generated when molecules are exposed to selected radio frequency waves. In fact, it is the electromagnetic energy used that is the key to the process.

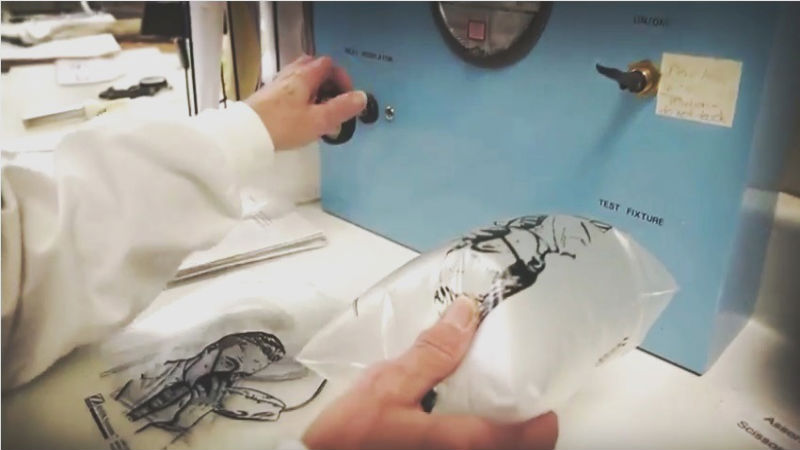

All radio frequency welding services use specialized equipment that uses two electrodes that develop an oscillating electronic field. As the field oscillates or alternates, specific molecules in the plastics respond and move. This movement, with sufficient energy, will cause the plastic to melt from both materials, creating a fusion or bonding.

At the same time, pressure is applied to the area to be sealed. The pressure assists in the fusion of the two plastics during the melting process. As there is no external heat source, only the exact area that needs to be bonded is exposed to the electromagnetic field.

This results in a very strong bonded and sealed area where desired, without any weakening or structural change in the surrounding plastic. The end product is a bond that will not leak, and that is consistent and even all along the seal.

Important Factors

It is important for companies offering radio frequency welding services to have experience in working with common plastics as well as those that are more challenging to work with. Additionally, issues such as using RF sealing on two different materials requires experience in setting the equipment and choosing compatible plastics and films to provide a top-quality bond.