Purchasing stock for a specific manufacturing process may sound straightforward but there is far more to it than you may realize. Stock may seem like a big piece of material, but that big piece of material can change the way the manufacturing processes are conducted.

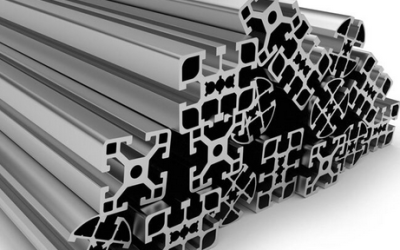

So, if your company needs extruded aluminum shapes for their next product, they need to be certain that the vendor can meet those needs. After all, custom extruded aluminum takes a certain level of skill that not all vendors possess.

Been There Before

The key to getting extruded aluminum shapes is to go with a company that has a track record for producing quality custom aluminum shapes. The best in the business have been around a long time for a reason.

That is because they are able to meet custom specifications no matter what they may be. They understand the specific and unique properties that aluminum possesses and can meet customer specifications down to the tiniest detail. It makes a huge difference throughout the manufacturing process.

Having the Right Tools

Part of making those cuts means having the best tools available to make them. It might mean doing an extruded piece of aluminum or a much larger quantity of aluminum plate. Whatever the order may be, having the right tools to make those precise cuts can make all the difference in the world in the quality of stock that you receive. Get precisely what your business needs to make the process go smoothly.