There are many different components and parts on aircraft, vehicles and equipment of all sizes that all rely on hard chrome plating to reduce friction and increase the life of the component.

In general, hard chrome, also known an engineered chrome plating or industrial chrome plating, is not used for decorative components, but with polishing and buffing after the process they can be finished to a mirror-like reflective shine.

The Process

Industrial chrome plating is electro-chemical process that uses electroplating principles to move chromium in a chromic acid solution to the surface of a metal object. The process can be carefully controlled to allow a very tight tolerance for the actual plating thickness, which is essential for many types of military, aerospace, machine tools, pumps, medical equipment and in hydraulic systems.

There are several steps that can be required in the process of hard chrome plating depending on the part or component that is to be plated. Existing or used equipment that is being plated to restore original size or to repair the surface damage will require more preparation that new and unused components that are being plated.

As a general outline, parts will first be carefully decreased to remove any surface residue. This will be done by the use of specific chemical solvents that will remove grease, oil or other surface contaminants across the entire exposed areas of the component.

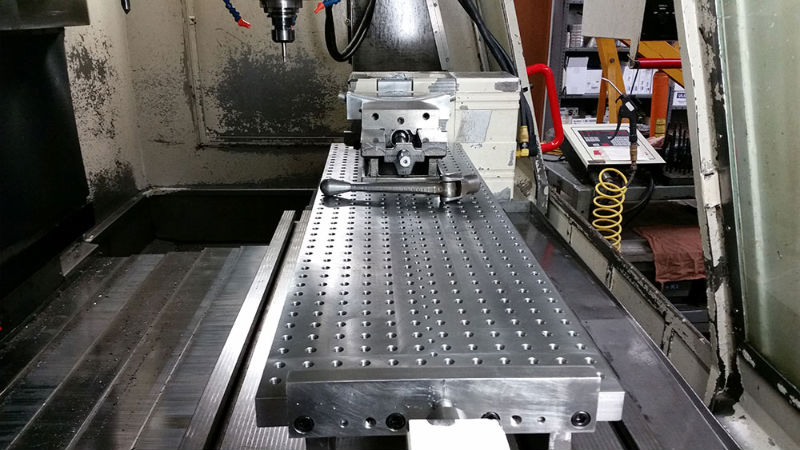

After this process, there will be pre-treating that will depend on the type of part and the substrate. This can include grinding or sandblasting to remove surface irregularities.

Once the part is completely prepped and prepared, it is then placed into the vat of chromic acid and exposed to the controlled electrical current. The component remains in the vat until the desired thickness is achieved. Temperature and substrate will determine the length of time the process takes.

Finishing

While most hard chrome plating is done to enhance wear resistance and to allow a part to move with limited friction, finishing is typically not to the polished and reflective levels of decorative chrome.

Finishing can be done when parts or exposed, or when additional lubrication, ease of movement or when requirements call for the additional surfacing processing. Buffing and polishing can be completed components and parts or only on specific areas of parts.

The term hard chrome actually refers to the thickness of the plating and that it can be tested for hardness. It is not a different process that decorative chrome plating, but it is very specialized and has a different desired end result.